APPLICATION FOR SWIMMING POOL

Dosage of MM-500 for Swimming Pool

Use 300 ml of MM-500 for every 50 kg of cement for all components of swimming pool: bottom slab, walls, and drains.

Water Cement Ratio for Swimming Pool

Recommended water cement ratio:

- A. Use 40% of water for washed or wet aggregates/(SSD Condition)

- B. Use 50% to 55% of water for dry aggregates.

Mixing

When using MM-500:

Mortar mixing machine – Dilute MM-500 in water for the batch, mix with cement & aggregates. For proper inclusion, 24 revolutions recommended.

Ready Mix Truck – Add MM-500 directly into the truck at site. For proper inclusion, 24 revolutions recommended.

Water Proofing Cement Grout for Swimming Pool Joints

To achieve monolithic bonding of blocks between new and old joints of concrete:

- A. Make cement grout by mixing 12.25 kgs of cement, 12.5 liters of water, then add 1 liter / 33.80oz of MM-500.

- B. Pressure-wash the joint key thoroughly if needed.

- C. Thoroughly brush on MM-500 grouting to the surface.

- D. Pour new concrete on and properly vibrate to achieve proper compaction.

Recommendations for Swimming Pool

- A. To achieve leak proof for high performance concrete (HPC), it is suggested to use strong formwork. This will enable proper compaction as extra vibration can be applied.

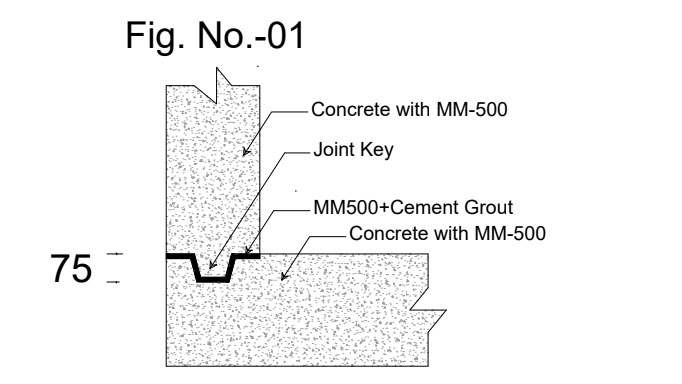

- B. To achieve stronger bonding and leak proof the concrete, it is recommended to follow the construction joint drawing as per fig: 1, 2 & 3.

- C. Before using MM-500 Cement Grout please thoroughly clean the surface with water pressure or with a steel brush.

- D. After using MM-500 with the cement grout it is suggested to apply proper vibration to compact the concrete to get high performance concrete (HPC). Excessive vibration will not cause segregation; thus, it will not be required to use PVC water stopper at the joint of the swimming pool.

Curing

Curing influences the overall quality of the concrete structure; thus, proper curing techniques are important to prevent the concrete from shrinking, drying, and cracking especially at the surface. Other than standard procedures no other special curing methods are required. MM-500 helps the concrete to hold the water for self-curing.

Cement Grout Joint's Figure

- A. Clean the surface with pressured water.

- B. Make cement grout with 1 liter of MM-500, 12.5 kg of cement and 12.5 liter of water. Area covered 4.65 sqm (50 sqft).

- C. Apply the MM-500 grout on clean surface with a brush broom properly.

- D. Pour concrete and properly vibrate.

- E. It is not mandatory to use PVC water stopper at the joint of swimming pool.

- F. Installation to be complete in accordance with manufacturers specification and recommendations.

- G. Drawing not to scale.

- H. These drawings are for informational purposes only and may not be used for construction.

- I. All information contained herein was current at the time of development but must be reviewed, consulted, and approved by the product manufacturer to be considered accurate.

- J. Contractor's note : For product and company information visit www.multimixco.com